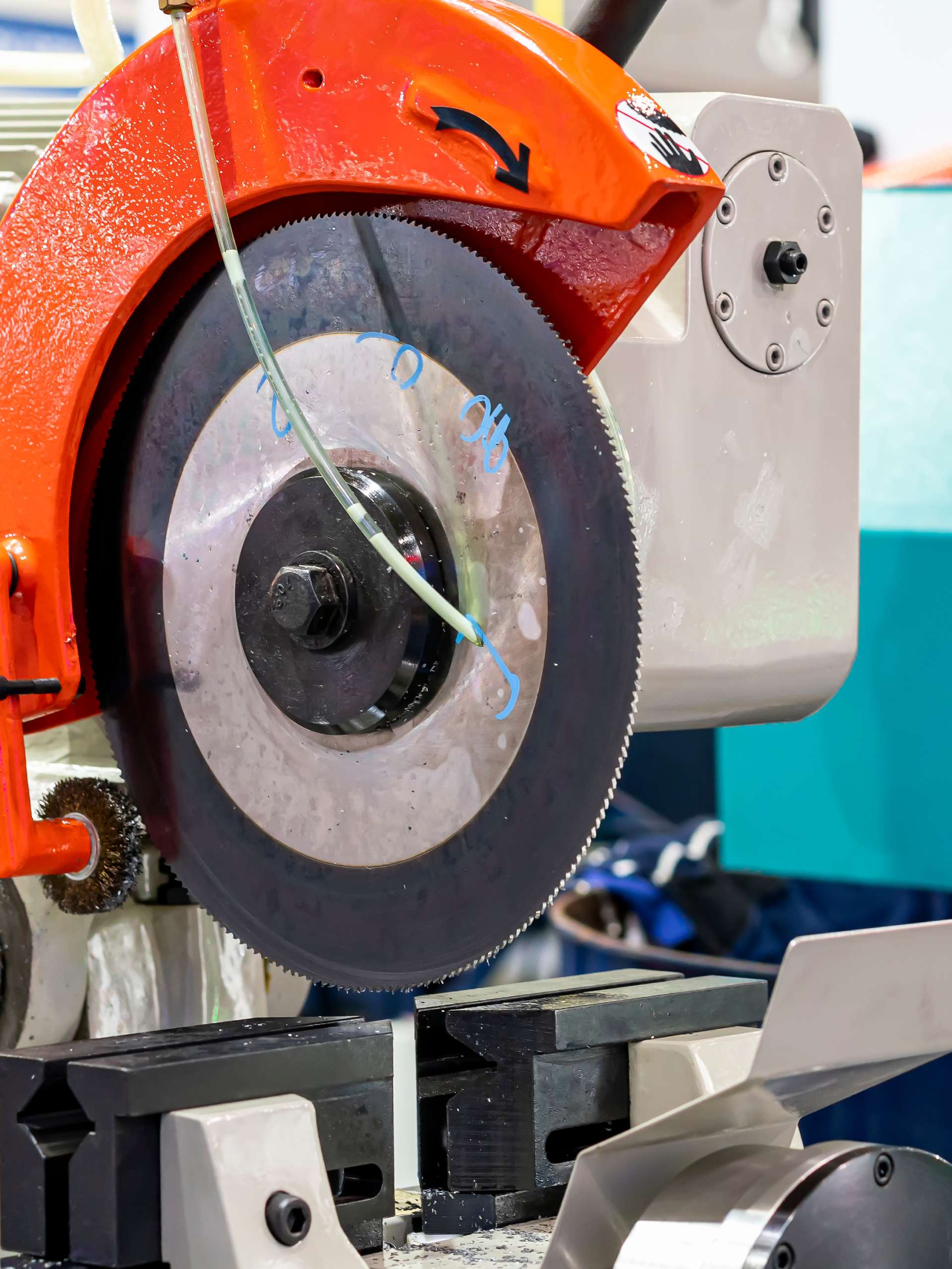

Cold saws are a staple in the metalworking and construction industries. They offer precision cuts thanks to their circular, toothed blades that operate at low speeds. This process ensures minimal heat generation and preserves the integrity of the blade and the material. Understanding how to properly test your new cold saw blade is crucial for achieving optimal performance.

The Art of Blade Testing

Testing a new cold saw blade is more than just a routine task. It’s about ensuring safety and maximizing efficiency in your work environment. A well-tested blade reduces the risk of accidents and oversees smooth, accurate cuts. Ignoring this step can lead to blade damage, poor performance, and increased costs over time.

Why Blade Testing Matters

Properly testing your new cold saw blade can save you from costly errors. A blade that hasn’t been tested might not perform as expected, which could lead to imprecise cuts and wasted materials. Investing a little time in testing can save significant resources and make sure your projects run smoothly.

Breaking In Your Cold Saw Blade

Breaking in a new cold saw blade is essential for prolonging its lifespan. Start by using the blade on softer materials at a moderate speed. This approach aligns the teeth and makes sure the blade adjusts to operational stresses. Avoid rushing this step if you want to enjoy long-lasting performance.

Techniques for Effective Blade Testing

When testing, always begin with a test cut. Choose material similar to what you will work with regularly. Observe how the blade performs and make a note of any irregular vibrations or noises. These can indicate issues that need addressing before full operation.

Interpreting Test Cut Results

Carefully inspect your test cut for clean, smooth edges. Rough cuts or burrs suggest the blade might need further adjustment. Clear, precise cuts indicate that the blade is ready for more demanding tasks. This insight can help you decide when a blade is suitable for specific projects.

Avoiding Common Testing Errors

Common mistakes during blade testing include rushing the process or testing on inappropriate materials. Skipping the break-in period can ultimately shorten the lifespan of your blade. Always follow manufacturer guidelines for the best results when changing out your cold saw blade.

The Importance of Regular Blade Maintenance

Regular blade maintenance is key to safe and efficient operation. After testing, make sure to inspect the blade for wear and tear regularly. Addressing issues early can prevent them from becoming costly problems down the line.

How Testing Fits Into Regular Maintenance

Incorporate blade testing into your regular maintenance routine. Regular testing after changing out your cold saw blade will keep your equipment in peak condition. This practice saves time and money over the lifespan of your tools.

Testing and maintaining your cold saw blade properly are investments in your operations. It oversees precision, safety, and longevity in all your cutting tasks. Make this practice a fundamental part of your routine to enhance project outcomes and maintain a professional standard in your work.

Casey Cartwright

Latest posts by Casey Cartwright (see all)

- What To Know About Ground-Up Range Construction – May 9, 2025

- 5 Safe Places To Park Your Car for an Overnight Hunting Trip – May 8, 2025

- 6 Essential Accessories Every Rooftop Camper Needs – May 7, 2025

Leave a Reply